|

|

50PIN SCSI Connector for Servo Motors with 1000V Voltage Rating and Moog Gender Design

|

Datos del producto:

Pago y Envío Términos:

|

| Género: | Moog | Resistencia de aislamiento: | 10PIN |

|---|---|---|---|

| Clasificación de voltaje: | 1000V | Tipo de terminación: | Engarzado/Soldadura |

| Calibre del cable: | 18-24 AWG o más AWG 3-12 de diámetro | material: | Metal/Plástico |

| Nombre: | Conector Moog ITT | Temperatura de funcionamiento: | -40 ℃ a +105 ℃ |

| Resaltar: | 50PIN SCSI Connector,1000V Voltage Rating Servo Motor Connector,Moog Gender PCB Connector |

||

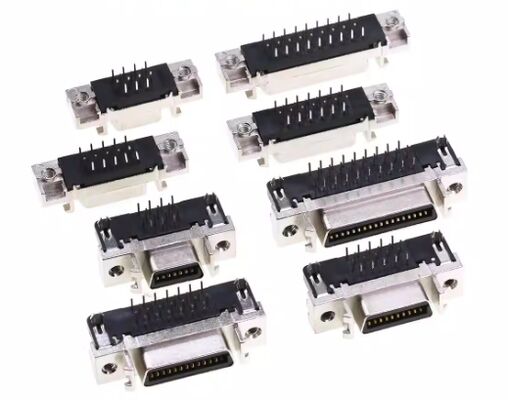

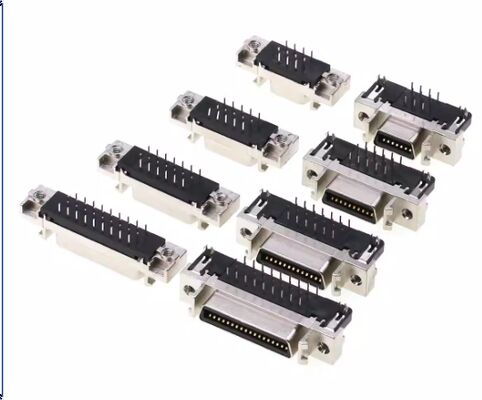

SCSI connector 14P 20P 36P 50PIN female straight pin and bent pin CN slot type female socket for PCB MDR servo

![]()

![]()

![]()

Product Description:

Servo motor connectors are critical components designed to ensure reliable and efficient connectivity in various servo motor applications. These connectors are specifically engineered to support high-performance devices such as High Torque DC Servo Motors, Electro Hydraulic Servo systems, and Brushless Servo Motors. With an emphasis on durability, precision, and electrical integrity, servo motor connectors play a vital role in maintaining optimal signal transmission and power delivery within servo motor assemblies.

One of the standout features of these servo motor connectors is their impressive current rating tailored for battery-powered applications. This makes them ideal for use in environments where stable and consistent power supply is essential to the operation of servo motors. The connectors are crafted to handle the unique demands of battery-driven systems, guaranteeing that the motor receives the necessary current without interruption or loss of efficiency.

The number of contacts available in these connectors is modeled after Omrons Domestic standards, offering a configuration that supports complex wiring schemes. Specifically, the connectors come with 10PIN configurations, which provide multiple channels for signal and power transmission. This multi-contact design ensures that each wire can be securely connected, reducing the risk of loose connections and signal interference that could otherwise hinder motor performance.

Insulation resistance is paramount in servo motor connectors to prevent electrical shorts and maintain safety. These connectors boast high insulation resistance, which preserves signal integrity and protects the motor and control circuitry from potential damage caused by electrical leakage. This feature is particularly important in high-torque and high-speed applications where electrical stability is crucial for precise motor control.

Designed to accommodate a wide range of wire gauges, these connectors support wire sizes from 18 to 24 AWG or more, including AWG 3-12 diameter wires. This versatility allows them to be used in diverse servo motor setups, whether the application requires thin, flexible wires for signal transmission or thicker cables for power delivery. The ability to handle various wire gauges enhances the connector’s adaptability across different servo motor types and installation conditions.

The gender of the connectors follows the Moog design specifications, ensuring compatibility with a broad array of servo motor systems. Moog connectors are known for their robust construction and reliable mating mechanisms, which contribute to long-lasting connections that can withstand mechanical stress and environmental factors. This gender specification guarantees that the connectors will seamlessly integrate with Moog-based servo motor assemblies, providing a secure and stable interface.

In applications involving High Torque DC Servo Motors, these connectors are engineered to manage the demanding electrical and mechanical stresses associated with delivering high torque output. Their sturdy construction and reliable contact design help maintain consistent power flow and signal quality, enabling precise motor control and efficient operation.

For Electro Hydraulic Servo systems, which combine electrical control with hydraulic power, these connectors offer the necessary electrical performance to support complex control signals and power requirements. Their high insulation resistance and multi-contact configuration ensure that signals are transmitted accurately without interference, supporting the sophisticated control algorithms used in electro hydraulic applications.

Brushless Servo Motors, which are favored for their efficiency and low maintenance, also benefit from these connectors. The connectors’ ability to handle multiple contacts and various wire gauges makes them ideal for the intricate wiring often found in brushless motor systems. Their robust design helps maintain the integrity of the electrical connections, contributing to the motor’s overall reliability and performance.

In summary, servo motor connectors designed with battery current ratings, 10PIN Omrons Domestic contacts, high insulation resistance, support for 18-24 AWG or larger wires, and Moog gender specifications provide an optimal solution for a wide range of servo motor applications. Whether used with High Torque DC Servo Motors, Electro Hydraulic Servos, or Brushless Servo Motors, these connectors ensure dependable, efficient, and secure electrical connections that enhance motor performance and longevity.

Features:

- Product Name: Servo Motor Connectors

- Insulation Resistance: 10PIN

- Number of Contacts: Omrons Domestic

- Contact Plating: Silver Pin and Golded Pin

- Application: Industrial Automation

- Termination Type: Crimp/Solder

- Compatible with AC Servo Drive systems

- Suitable for AC Brushless Servo Motor connections

- Designed for reliable performance in AC Servo Drive applications

Technical Parameters:

| Insulation Resistance | 10PIN |

| Material | Metal/Plastic |

| Connector Type | Servo Motor |

| Voltage Rating | 1000V |

| Mounting Type | Panel Mount/Cable Mount |

| Wire Gauge | 18-24 AWG Or More AWG 3-12 Diameter |

| Termination Type | Crimp/Solder |

| Number of Contacts | Omrons Domestic |

| Application | Industrial Automation (AC Servo Drive, AC Brushless Servo Motor, Hydraulic Brake Motors) |

| Gender | Moog |

Applications:

The NO MARK servo motor connector, model number servo motor connector, is a high-quality product originating from China, designed specifically for industrial automation applications. Certified by CE and ISO9001, this connector ensures reliable performance and durability in demanding environments. With a current rating suitable for battery applications and compatibility with wire gauges ranging from 18-24 AWG or even larger diameters of AWG 3-12, it offers versatile connectivity options for various servo motor systems.

This Moog ITT Connector, tailored for Moog gender specifications, is ideal for use with Hydraulic Brake Motors, High Torque DC Servo Motors, and AC Servo Drives. These applications demand connectors that can handle high current loads and maintain secure, stable connections during operation, which this servo motor connector is engineered to provide. Its robust construction and precise design make it an excellent choice for automation systems requiring high reliability and efficiency.

The servo motor connector is perfect for manufacturing plants, robotic assembly lines, and automated machinery setups where seamless communication between servo motors and control units is critical. It supports rapid installation and maintenance due to its user-friendly design, minimizing downtime in fast-paced industrial environments. The packaging in sturdy carton boxes ensures safe transportation and easy storage, matching the supply ability of 1000 pieces per day to meet large-scale production demands.

Customers can order a minimum quantity of 100 units, with delivery times ranging from 1 to 3 working days, facilitating quick project turnaround. Payment terms are flexible, accepting T/T and PayPal, making procurement convenient for international buyers. Whether integrating with Hydraulic Brake Motors for precise braking control, High Torque DC Servo Motors for heavy-duty torque applications, or AC Servo Drives for variable speed control, this connector ensures stable and efficient connections vital for optimal machine performance.

In summary, the NO MARK servo motor connector is an indispensable component in the realm of industrial automation, offering exceptional compatibility, certification-backed quality, and rapid supply chain support. It stands out as the preferred choice for engineers and system integrators aiming to enhance the reliability and efficiency of servo motor-driven systems across diverse industrial scenarios.

Customization:

Our servo motor connectors, branded NO MARK and model number servo motor connector, are manufactured in China with strict adherence to quality standards, certified by CE and ISO9001. We specialize in product customization services to meet the specific needs of AC Brushless Servo Motor, Brushless Servo Motor, and Hydraulic Brake Motors applications.

With a minimum order quantity of 100 pieces and a supply ability of 1000 pcs/day, we ensure timely delivery within 1-3 working days. Our connectors are made from high-quality metal and plastic materials, featuring contact plating options of silver or gold-plated pins for reliable electrical performance.

Designed to support a current rating suitable for battery applications and a voltage rating of up to 1000V, these connectors offer versatile termination types including crimp and solder, providing flexible installation options.

All products are securely packaged in carton boxes to guarantee safe transportation. We accept payment terms via T/T and PayPal, making transactions convenient and secure for our clients.

Choose our customized servo motor connectors to enhance the performance and reliability of your AC Brushless Servo Motor, Brushless Servo Motor, and Hydraulic Brake Motors systems.

Support and Services:

Our Servo Motor Connectors are designed to provide reliable and secure connections for servo motor systems. These connectors ensure optimal performance by minimizing signal loss and enhancing electrical conductivity.

Technical support for our servo motor connectors includes assistance with product selection, installation guidance, and troubleshooting. Our team is equipped to help you identify the right connector types and configurations to match your specific servo motor requirements.

We offer comprehensive services such as connector customization, testing, and quality assurance to meet the highest industry standards. Additionally, we provide detailed documentation and user manuals to facilitate proper usage and maintenance.

For any technical inquiries or support needs related to our servo motor connectors, we encourage customers to reach out to our dedicated support team who are committed to delivering prompt and effective solutions.

Persona de Contacto: Zhou

Teléfono: +8613316962478

-

Los conectores para servomotores ASD-MDBT0100

-

Conectores de cable de servomotor de tipo M23 M40 E P 17 pin 12 pin

-

SM-6E 6E SM Servo conectores conjunto completo IEEE1394 6 piezas femeninas de núcleo

-

SM-6P servo MOLEX SM6P 1394 6 PIN Male Female Connector

-

Conectores del motor servo de J17S-06FMH-7KL-1M-CF PA66 con la primavera Stell

-

Panasonic Servo I/O Control Plug Driver X4 Connector DV0P4350 DV0P0770 26 50-pin